We have invited our local technical high school, Assabet Valley Regional Technical High School to come visit our shop and learn some interesting information. This was a chance to inform students about the world of manufacturing. We took them on a tour of the facility and showed several examples of parts.

Our goal is to enhance the knowledge of young minds and gain interest in the manufacturing world! We have hired several employees from this particular school and hope to keep building the relationship.

As a member of PMPA, Precision Machined Products Association, we want to encourage careers in manufacturing. The goal is to open up shop floors around the country and show communities what modern-day manufacturing is all about.

Students view several different parts from all market segments prior to their tour.

Eric Doody, Quality Manager, goes over quality procedures and shows a demonstration on the Keyence machine. Eric discussed the importance of quality inspections on all parts prior to leaving our facility.

Steve Doody, President, takes students for a tour around the shop. Students were able to have a first hand look inside the machines and ask any questions they had.

Domingo Jimenez, Production Manager, discusses scrap material and chips coming off of the machines during production. Domingo explained to students the value of scrap material.

The CSI Group is expanding to meet needs of customers all over the globe.

Welcoming Vardeco SA:

An impressive display of their equipment, located in Switzerland.

SAMs Process – Self Assembled Molecules

What is the SAM’s process and the benefits?

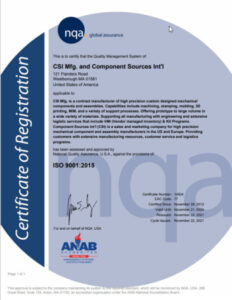

Component Sources Manufacturing, a part of the CSI Group located in Westborough, MA, has been ISO certified to the medical quality specification ISO 13485:2003. CSI Manufacturing is a contract manufacturer specializing in high precision machined components. Capabilities include prototype development to large volume production in a variety of materials, hardness and plating requirements.

Hard Materials Include:

Alumina Boron Carbide

Glass / Ceramics Ruby / Sapphire

Silicon Carbide Silicon Nitride

Tungsten Carbide Zerodur

Zirconia

We currently produce parts in hard materials for the Aerospace, nuclear, military, optics, medical and instrumentation markets. We are producing parts for the following applications:

A solution to every wear problem…. We are a leader in the production of parts made from very hard materials.