Supply chains have a huge impact on company profits, so optimization and cost reduction are always valuable. Today, most manufacturing industries face many supply chain challenges such as raw material shortage, slow responsiveness from suppliers due to capacities, compliance with government regulations, plus timely delivery to their supply chain partners.

As a direct and fast solution to overcoming these current supply chain challenges, CSI Group provides a unique service to ensure your procurements on high precision mechanical products.

Capacities

Modern machine shop giving access to +1,000 machines including CNC machines, Swiss Cams and Transfer, Escomatic wire machines, Multi-axis milling centers, Multi-spindles…

Send us your inquiry and get a quote

xExpertise

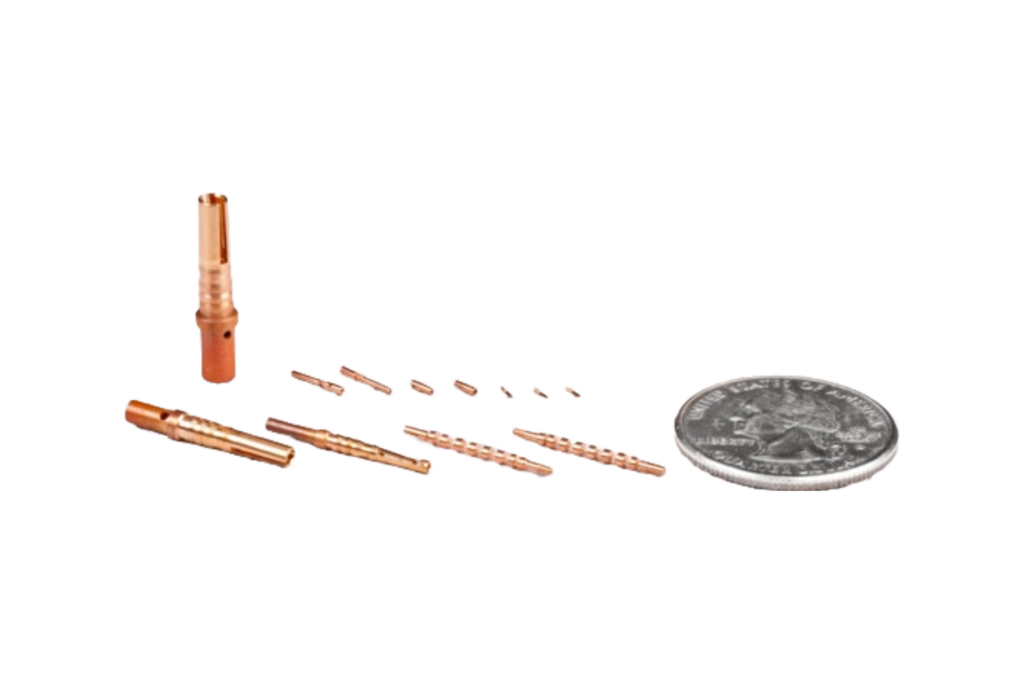

With over 30 years of experience, we are leaders in manufacturing high precision machined components for high end industries such as electrical interconnects, sensors, aerospace and defense applications, automotive…

Secure

To support increasing demand, we closely work with our customers to prioritize production planning and anticipate any supply chain shortage (stock, Kanban, VMI…)

CSI Group’s Engineering Expertise is the resource that will provide the solution. CSI Group has over 30 years of component design experience. Our Engineering Team understands the supplier, equipment, process, and capabilities that ensure the successful manufacturing of top-quality parts from concept through component usage in the specific application.

Success Story: CSI and a world-class designer/manufacturer of connectors collaborated successfully in simplifying designs for connector contacts. It was evident that trust developed between these two companies when the customer reached out multiple times requesting the expertise of CSI’s Engineering Team to review new designs. The partnership resulted in CSI receiving multiple purchase orders and the customer receiving a reduction in cost and lead-time for the simplified designs.

To learn more about CSI’s capabilities www.compsources.com

For CSI Group’s Engineering Expertise / to send an RFQ – email us at sales@compsources.com

Our Sales Team will be in contact with you shortly.

CSI and a top manufacturer in the battery industry teamed up to redesign and develop a critical component used in battery manufacturing. The specific use of this strategic component is the precise dispensing of electrolyte in every single battery.

CUSTOMER OBJECTIVE Reducing the ‘carbon footprint’ of their products

SOLUTION CSI

BENEFITS Great collaboration, Successful design improvement, Price reduction, Local sourcing

CUSTOMER ACHIEVEMENT Developing a reliable local sourcing partnership that assisted in achieving the objective

To learn more about CSI’s capabilities

Send us a RFQ by email at sales@compsources.com or Contact Us – Our Sales Team will contact you shortly.

CSI is collaborating with a leading customer in the Sensor industry and they are closing in on a solution for one of the highest volume “Bread and Butter” sensors products that the customer sells.

To learn more about CSI’s capabilities

Send us a RFQ by email at sales@compsources.com or Contact Us – Our Sales Team will contact you shortly.

The Most Valuable Business Commodity is….?

From the words of Richard Branson (a wealthy and influential British businessman), “the most valuable business commodity is TRUST.” How those words ring true here at CSI Group.

CSI Group has spent 2 years building strong relationships with a leading sensors company which resulted in a big win – a customized Probe Mandrel Assembly, including multiple processes.

The CSI Group’s Engineering Team supported the customer in the redesigning of the components, defining the best material and dimensions. Due to this strong collaboration, we jointly designed a better solution with requested higher temperature materials, easier assembly, and a significant cost reduction.

This collaboration strengthens our relationship and builds a lot of trust in CSI Group’s capabilities and support. Trust, collaboration, and expertise are keywords for a long and valuable business relationship.

Send us your contact details or RFQ by email at sales@compsources.com

CSI Group / Hugard Inc Production Site Expansion We are excited to announce the expansion of our production site. A new adjacent 5,000 square foot building will allow us to increase our production capacity and strengthen relationships with our existing and future customers.

This new production area will accommodate 4 more brand new CNC machines in addition to our current production tools (32 CNC machines). Two of these machines will be arriving in August 2021 to meet the growing demand on machined parts.

With CSI Group / Hugard Inc Production Site expansion, we are highly motivated to better serve and support our customer’s requirements on any mechanical high precision component and assembly project. www.compsources.com / www.hugard.com

Send us your contact details or RFQ by email at sales@compsources.com

CSI Group Collaboration is a Key to Success

CSI Group worked together with one of our customer’s Engineering Team from a leading Medical company in developing a newly designed high precision component with a very tight tolerance – a surgical tool.

From this collaborative effort, the end results were substantial cost savings and a higher quality tool, but more importantly, our customer had a positive and successful experience in working with CSI Group to jointly design and produce a product that met the customer’s standards and industry approval.

Learn more about our capabilities and the way we can support you with your Engineering projects. CSI Group collaboration is a key to success for your future custom designed mechanical components and assembly projects.

Contact CSI Group sales@compsources.com

At the heart of every successful manufacturing company is an exceptional supply chain. CSI Group can help you with supplier reduction by being your one source solution.

At the heart of every successful manufacturing company is an exceptional supply chain. CSI Group can help you with supplier reduction by being your one source solution.

If your organization purchases mechanical components and assemblies, we can help you identify, deliver, create cost savings and reduce risks through using the best manufacturing process. The savings you achieve have a direct and immediate impact on your bottom-line, increasing profits and adding lasting value to your business.

CSI Group is an ISO / ITAR certified leader in precision mechanical components and assemblies. We designed our unique corporate model to help customers with supply chain consolidation, from pre-production analysis and engineering through final inspection and inventory management. Our engineering and logistic teams will become yours.

We bring 35 years of sourcing with our group of over 1,000 machine tools and 11 manufacturing processes from USA and Europe. At our Westborough, MA facility, we operate over 30 CNC machine tools to offer the most complete capabilities, provide multiple technologies and define the right process through our “one-sourced” model.

Click on the link to see our line-card and it has more information about our company.

Send us your contact details or RFQ by email at sales@compsources.com

Our sales team will contact you shortly.

CSI Group is committed to investing in technology that reduces cost and lead time. We are very excited to announce that we have implemented a platform that is streamlining the quote-to-order process for our customers by offering Interactive Digital Quotes with Rapid Part Checkout. The new platform is fully secure and ITAR compliant.

Submit a request for quote and let us know what you think!