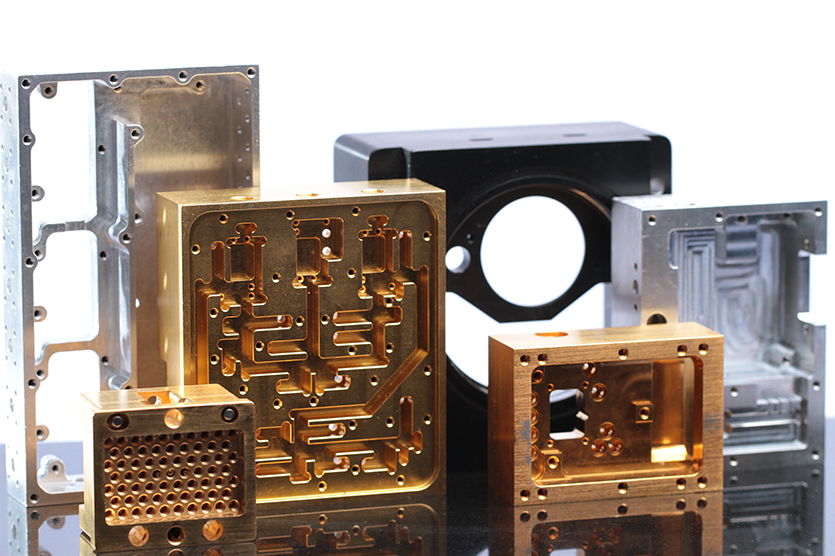

1 Source Solution for Precision Machining Capabilities

Through our consortium of multiple Partners (USA/Europe), CSI Group provides all required operations from component manufacturing to assembly.

Additional Capabilities

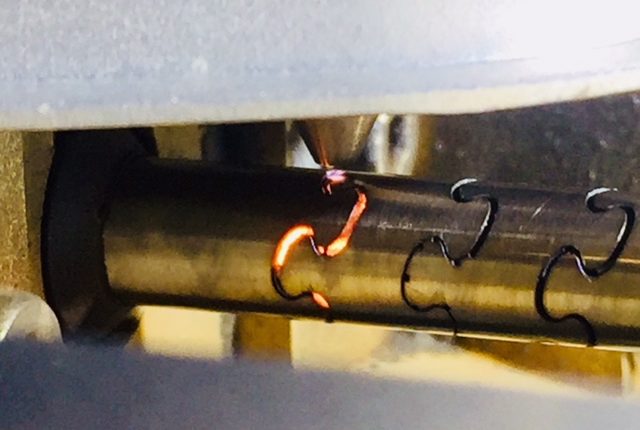

Laser Cutting

From prototypes to small and large volumes, we offer specific and technical solutions to ensure precise cutting quality with or without post treatment.

Standard Metals Aluminum, Bronze, Copper Alloys, Inconel, Nitinol, Stainless Steel, and Titanium

| Tube Cutting | Strips Cutting |

|---|---|

| Diameter: up to 30mm | Sheet to sheet loading |

| Tube Thickness: 1mm max | Dimensions: up to 108x74mm |

| Standard Accuracy: 10 microns | Thickness: 1mm max |

| High Accuracy: +/- 3microns | |

| Stents and hypotube cuts |

Laser Welding

With new generation CN equipment, we are enabled to assemble metal components to weld prototypes to high volumes utilizing various methods.

Standard Metals Aluminum, Copper, Stainless Steel, Steel, and Titanium

Exotic Materials Anvar, Chrome-Cobalt, Inconel, Kovar, Molybdenum, Nickel Alloys, Nitinol

- Robotic Laser Welding Cells allows for Pulsed, Continuous, Disc, Fiber and Diode Laser

- Additional Techniques TIG, MicroTIG, Orbital, Micro-Plasma, Electric and Micro-Electric

Metal Injection Molding (MIM)

Metal Injection Molding (MIM) is an advanced metal forming process that allows complex parts to be shaped in a single operation and in high volume. A perfect solution for creating small and complex metal components.

Metal Stamping

With expertise in both low and high volume precision small part metal stamping, our focus is on sheet metal stamping which offers a fast and economical process for producing high quality parts with extremely tight tolerances. Standard Quantities: 50 to Millions

Plastic Injection Molding (PIM)

Plastic Injection Molding is an advanced plastic forming process that allows complex parts to be shaped in a single operation and in high volume. A perfect solution for creating small and complex plastic and composite material components.

Sheet Metal Fabrication

Sheet Metal Fabrication is used for producing high quality formed parts out of various materials such as aluminum, hot and cold rolled steel, stainless steel, copper and others.

3D Printing

With a continued push to develop our additive manufacturing capabilities, we have integrated 3D Printing technology to allow us to prototype and manufacture complex parts that are not feasible through traditional manufacturing methods. Some of the additive processes offered are Stereo Lithography (SLA), Selective Laser Sintering (SLS), Metal/Plastic Printing.

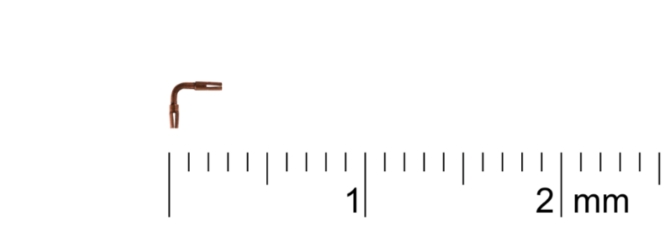

UV LIGA Technology is a unique technique in manufacturing micro components. This procedure combines photolithography and electroforming. The advantages of this technology are inexpensiveness and quick implementation.

Learn more about this unique technology in manufacturing micro components, click Mimotec.